Scratched Hard Drive Platter Data Recovery

Hard drive platter damage was once a data recovery engineer’s worst nightmare (for many labs, it still is). But thanks to Gillware’s advances in scratched platter data recovery techniques, scratched platters are much less of a nightmare. To learn more, read on and find out how we handle scratched hard disk platters:

If you’re on this page, your computer probably stopped booting up, or your external hard drive started clicking or beeping. You’ve probably been told, either by a computer repair professional or another data recovery lab, that your data cannot be recovered because your hard drive has scratches on its platters, and you’re probably here because you need a second opinion.

Fortunately, you’ve come to the right place.

What makes recovering data from scratched hard drive platters so challenging that until recently, it was nigh-impossible?

To understand the threat of scratched platters, first, you have to understand what hard disk platters are.

RELATED ARTICLES:

What Are Hard Drive Platters?

The platters are the disks in your hard disk drive that contain all of your data on the thin layer of platinum alloy coating the surfaces. Modern hard drive platters are either 2.5 inches or 3.5 inches in diameter. They are like CDs or DVDs, but smaller and more complex. They also store their data quite differently.

CDs, DVDs, and Blu-Ray disks are optical data storage media. Little pits are arranged on the disks so that a laser can read the pits as “0”s and the gaps between them as “1”s. These “0”s and “1”s comprise all the data on the disks.

Hard drive platters, on the other hand, are magnetic storage media. Their surfaces are completely flat and covered with a thin layer of magnetic substrate made from platinum and a handful of other metals. Which parts of the disks are “0”s and which are “1”s is determined by the magnetic field of incredibly tiny portions of the coating on the disks.

Hard drive platters have billions of these regions per each surface of the platter, and hard drives have several platters inside them.

The tiny read/write heads inside your hard drive can pick up or alter the magnetic signals given off from the platters. To read data, an electrical signal produced by the platter’s magnetized surface travels through the heads.

To write data, an electrical signal travels the other way and alters the magnetic field of that tiny sector of the platters. Some “0”s turn into “1”s. Some “1”s turn into “0”s. Some stay the same.

This sounds like a complicated process that your hard drive has to do millions of times every time you use it.

And it is. Your hard drive just does it all very, very quickly. In modern hard drives, the platters are spinning at from 5,400 to as many as 15,000 revolutions per minute.

Do you have questions about recovering data from scratched platters?

How Do Scratched Hard Disk Platters Impede Data Recovery Efforts?

The read/write head assembly inside your hard drive hangs precariously close to the platters’ surfaces. If they make contact with the platters at any time, they can gouge out part of the thin layer of platinum alloy coating that holds your data.

This turns what once was a part of your family photos to dust, which can get embedded in other segments of the platters. The dust kicked up by a head-platter collision presents on its own a significant barrier to data recovery. That dust can’t be returned to its rightful place on the platters, which means the data on the damaged part of the platters is gone. Forever.

But the damage done doesn’t stop there.

How to Clean a Hard Disk Platter

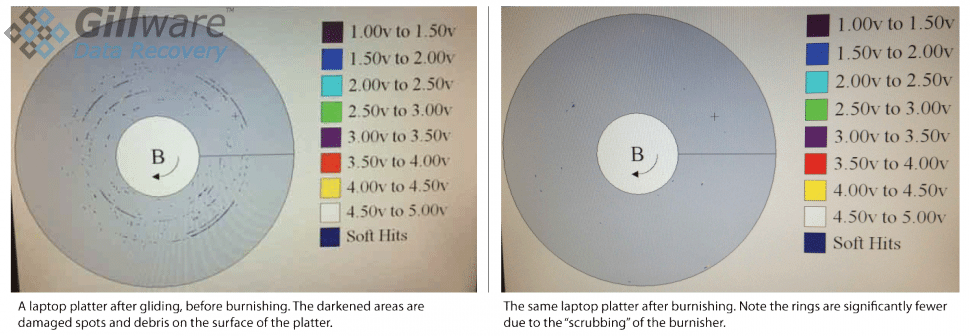

Hard disk platters aren’t as easy to clean as other disks, like CDs or DVDs. If a hard disk platter has accumulated debris on it from floodwater, fire damage, or internal damage, it must be carefully removed from the hard drive’s chassis in an environment that meets ISO 5 Class 100 clean air standards (i.e. a data recovery lab), cleaned with deionized water and microfiber cloth, and burnished to remove any embedded particulates before being returned to the hard drive’s chassis.

Even then, after cleaning the disk platters, the read/write heads must usually be replaced (since they are usually what was responsible for scratching the platters in the first place). In cases of severe environmental damage (flooding and fires, for example), the entire chassis must be replaced.

Read/write heads in your hard drive hover a few nanometers above a hard drive’s platters. This is such a small distance that from our perspective, they might as well be touching.

In order for the heads to do their job properly, the platters have to be perfectly smooth. A slightly raised area on a platter’s surface—such as a little bit of dust—can be devastating. For the read/write head, it’s like a car crashing into a mountain at 100 miles per hour. You can probably guess what happens next.

When a hard drive enters our cleanroom with damaged platters, it almost always needs its heads replaced. But if we can’t do anything about the dust and debris on its surface, what happens to the new set of heads? They’ll meet the debris on the platter and meet their maker. No progress will be made—all we have to show for our data recovery efforts is another set of dead heads.

For the longest time, even slightly scratched platters were a data recovery death sentence. It wasn’t just that the damaged areas were unrecoverable and nothing could actually repair the scratches. Because of the debris, recovering data from even the healthy sections of the platters was nightmarishly difficult as well—if not impossible.

This is why many data recovery labs to this day still throw up their hands and give up at the first sign of even minor hard drive platter scratches.

Gillware’s Scratched Platter Data Recovery Technology

After having to tell way too many people there was nothing we could do for way too many years, we here at Gillware finally said, “Enough is enough. Surely there’s a better way to clean the dust and debris off of damaged platters and give our engineers a fighting chance.”

And there was. We modeled our scratched platter data recovery techniques off of the same methods hard drive manufacturers will use to iron out the imperfections in their glass and aluminum hard drive platters.

When a hard drive’s platter come off the assembly line, it usually has its fair share of imperfections. This is just a natural result of the manufacturing process. But these imperfections need to be ironed out in order for the platter to be usable.

The manufacturers, therefore, burnish each platter’s surfaces before putting it into a hard drive chassis. This ensures the kind of smooth, polished surfaces the read/write heads need.

Our glide burnishing tools can dramatically reduce the amount of dust and debris standing in the way of our data recovery efforts. Glide burnishing takes a bumpy, lumpy hard drive platter and makes it ultra-smooth again.

The damaged parts of the platters still can’t be restored — Nothing short of reversing time itself can do that. But with the help of our burnisher, we can recover data from the rest of the platters.

Our glide burnishing tools can dramatically reduce the amount of dust and debris standing in the way of our data recovery efforts. Glide burnishing takes a bumpy, lumpy hard drive platter and makes it ultra-smooth again.

The damaged parts of the platters still can’t be restored — Nothing short of reversing time itself can do that. But with the help of our burnisher, we can recover data from the rest of the platters.

Some forms of platter damage are still severe enough to make scratched platter data recovery impossible. Sometimes, the read/write heads gouge out massive rings of data from the platters that wipe out huge amounts of user data or even destroy the drive’s firmware sectors. But platter damage is no longer the data recovery death sentence it once was.

Why Choose Gillware for Scratched Hard Drive Platter Data Recovery?

Our revolutionary glide burnishing techniques give us a leg up on a lot of other data recovery services. That said, some forms of platter damage do still make data recovery impossible. This is one of the reasons why we never charge any upfront fees for our entire scratched platter data recovery process.

Evaluation is free, and we even offer to cover the cost of inbound shipping. We don’t show you a bill until we’ve gotten everything we can from your hard drive. If the cost is too high for you, or we can’t recover the data you need, you owe us nothing. Our entire scratched platter data recovery process is completely financially risk-free. The last thing we want to do is take your money and give you nothing in return.

Gillware is beyond the shadow of a doubt the best option for scratched hard disk platter restoration and data recovery. Most data recovery companies will give up at the first sign of even the most minor scratches on a hard disk platter’s thin coating of magnetic alloys containing your data. They simply don’t have the resources to reliably or effectively clean off the dust and debris platter damage leaves in its wake. When that happens, you can take their word for it or look somewhere else for a second opinion. At Gillware, there’s no question about it–if there is data to be gotten back, you can rest assured we’ll get it.

Sadly, sometimes your data really is unrecoverable. Hard disk platter damage is the most severe kind of physical damage your hard drive can sustain, and there’s no going back from it. All the technology in the world, even ours, can’t help if the damage is too widespread or lands in exactly the right location on the disks.

The unfortunate truth that not all data is recoverable is the guiding principle behind Gillware’s mission to provide data recovery options that are as risk-free as possible.

If your scratched hard disk platters are too far gone for us to pull any data off of, you won’t owe us so much as a single dollar. You only pay us once we’ve recovered everything we can, and only if the price for the data we’ve recovered makes sense to you. Since you get free shipping to our data recovery lab and headquarters in Madison, Wisconsin, no fees for in-lab evaluations, and no upfront costs on top of our “no data, no charge” guarantee, our data retrieval services are truly financially risk-free.

Gillware’s Benefits

Cutting-Edge Hard Drive Repair Work

Industry-Leading Hard Disk Platter Restoration Tools

Free Inbound Shipping and In-Lab Evaluations

No Up-Front Fees

No Data, No Charge

Best Technology and Expertise

Expedited Emergency Service Options

Put your data in the safest and most skilled hands.

Need data recovered from a hard drive with scratched platters?