Data Recovery 101: Read/Write Head Assembly

In Gillware’s latest blog series, “Data Recovery 101″, our bloggers take a closer look at each of the different components of a hard drive and explain how they work, how they fail and how we recover the data from each failure situation. In this post, we’ll explore the read/write head assembly.

What are the read/write heads?

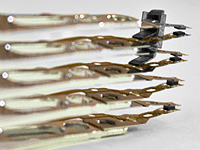

Read/write heads are the tiny sensors (about 0.1 – 0.3mm tiny) that do just what their name implies: read data stored on the platters and write data to the platter surface. Although some hard drive configurations involve just a single read/write head, most modern drives involve multiple heads stacked together to form what is referred to as a head stack assembly. The number of heads depends on the storage capacity of the drive. Higher capacity drives have more heads than lower capacity drives.

The head itself is little more than a tiny coil of copper. When reading data, the platters magnetic field induces an electrical current in the read/write head coil. This current is interpreted by the HDD’s controller as a binary 1 or 0. When writing data, the HDD controller sends current to the read/write coil which induces a magnetic field that alters the bits stored on the hard drive platter effectively “writing” data to the drive.

How do the mechanics of read/write heads work?

The read/write head is designed to behave like a very small wing. When the drive is running, the platters spin at thousands of revolutions per minute generating a significant amount of airflow inside the drive chassis. When this airflow impacts the heads, they lift just like an airplane lifts when it achieves enough airflow over its wings. In normal operation, the read/write head floats just 3-5 nanometers above the surface of the platters.

When the HDD receives a read or a write command, the heads seek to the area(s) of the platter where to which the data is to be read or written. In older drives, head positioning was controlled by a servo motor moving the read/write assembly across the platter surface. Servo motors were phased out over the years because they were a bottleneck preventing HDDs from meeting the demands of the market in terms of performance and drive capacity.

Servo motors were replaced as the head positioning component in HDDs with a much higher performance design commonly referred to as a moving coil motor. With this design, a coil of copper wire is attached to the end of the head stack assembly. The copper coil is sandwiched between two powerful magnets. When current is feed to the copper coil, a magnetic field is generated and the head stack is “pushed” and “pulled” to the correct position on the platter.

How do the heads fail?

As you may have guessed, the read/write heads are a common failure point in hard drives. They are one of the hardest working components inside a hard drive and also one of the most delicate. This, coupled with the fact that they are operating just a few nanometers above the surface of the platters, means that, although not common, failures can and do occur.

There are a number of different ways the heads can fail. For example, if the drive unexpectedly loses power due to an electrical surge, power outage or hard shut down, the cushion of air over the surface of the platters dissipates before the heads have a chance to repark properly. In this instance, known as a head crash, the heads can contact the delicate platter surface while they are still spinning, causing damage to the magnetic substrate on the surface of the platters where the data is stored, or damage to the heads themselves.

Head crashes, and consequently head failures, can also be caused by dragging a laptop across a desk, dropping and external hard drive on the floor, or simply as the result of mechanical fatigue or component wear. When heads fail, the HDD will often times make a clicking sound, which is the result of the head stack assembly flying blindly from one extent of the platter to the other. When the heads encounter the head stop, they make the clicking noise.

How can you recover data from crashed heads?

Recovering data from a hard drive with failed read/write heads may seem easy in theory. Just swap the bad heads out for a working head stack and voila, you’re done. However, there are a number of challenges that make replacing failed read/write heads difficult:

Finding correct donor heads:

It can be difficult to find the right donor heads for the failed hard drive. All read/write heads are not created equal. Heads change from manufacturer to manufacturer and from model to model. Modern hard drives are so sophisticated and tightly calibrated that the heads from two drives made one after the other on the production line may not be compatible with one another.There are two key factors that make Gillware very successful when it comes to replacing read/write heads. First, we have thousands of hard drives in our parts inventory that we can take donor heads from. The more parts we have in our inventory the more likely it is that we will find heads that closely resemble the heads we are looking to replace.Second, we have sophisticated techniques for tricking the patient drive (the drive from which we want to recover data) into accepting the heads form the donor drive. As we have already covered, just because we have a drive of the same make and model does not mean that the drive will accept and operate with the new donor heads.Just like the human body can reject a new organ, a hard drive can reject new components. Doctors get around this by administering anti-rejection drugs to the patient. Gillware can’t use drugs, but we CAN manipulate the hard drive’s firmware to accept the new parts. It may not like it and the performance will certainly be degraded, but when executed properly, data can be read and recovered.

Damage to other components:

If in the process of the heads failing there is damage to other parts of the drive (platter damage, electrical failures, motor failure) recovery can be made even more difficult. Especially in the case of platter damage, unless the damage is cleaned up or repaired, the replacement donor heads will inevitably meet the same fate as the original heads. They will be instantly killed.

Risk of contaminants on platters:

This is something to consider any time a hard drive is opened. Since the heads float just a few nanometers above the surface of the platters, even a single speck of dust or a fingerprint on the platters can have catastrophic results. Any invasive mechanical data recovery should be performed by reputable professionals in a dust-free ISO 5, Class 100 cleanroom facility.

To learn more…

In the posts to come, you’ll learn more about the different hard drive components we discussed in this post (electrical components, firmware and spindle motor) and how they work together to create a fully functioning hard drive. Additionally, we’ll show you what can go wrong with each of these components and how Gillware recovers data from different situations of hard drive failure.